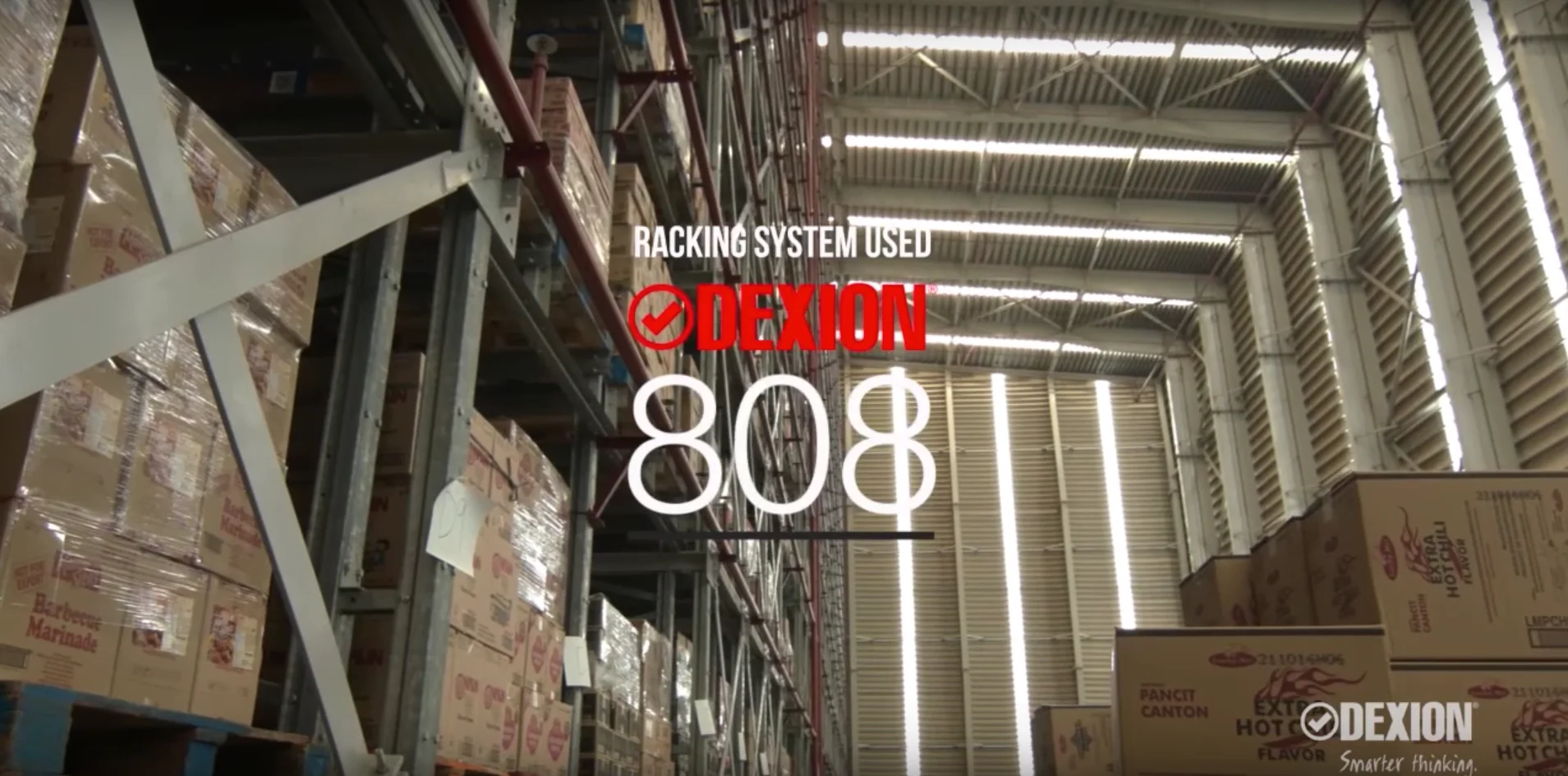

Streamline Automotive Operations with Smarter Thinking

We take pride in our thoughtful approach to automotive warehouse storage solutions. Understanding the vast number of SKUs, maintaining stock accuracy, and ensuring timely delivery to customers are key. Designing a warehouse to overcome these challenges will be a significant advantage for your business.

This is exemplified in our work with Mobis, Century Yuassa, and Toyota.

For Mobis, managing an inventory of over 80,000 parts was a considerable challenge. We provided a system capable of efficiently handling this large variety of stock, enhancing the picking and retrieval process. The integration of straightforward technology, like barcode scanning, has made sorting and dispatching orders more efficient and reliable.

Century Yuassa faced difficulties with stock rotation, especially for batteries with limited shelf lives. We simplified their order picking process, establishing easily accessible picking locations at lower levels, improving overall efficiency and maintaining product condition.

For Toyota, the requirement was for a storage solution that was effective, tidy, and professional, in line with their AFM and Toyota standards. Our shelving system met these criteria, offering the flexibility required for ongoing kaizen activities. By using fewer uprights, we increased storage space and achieved cost savings.

In each case, Dexion’s approach has been to provide practical and effective solutions, underlining our commitment to enhancing automotive warehouse storage.