Optimise F&B Operations with Smarter Thinking

At Dexion, we apply a smarter thinking approach to tackle unique challenges in Food & Beverage warehouse storage, as seen in our projects with Monde Nissin and Kellogg’s.

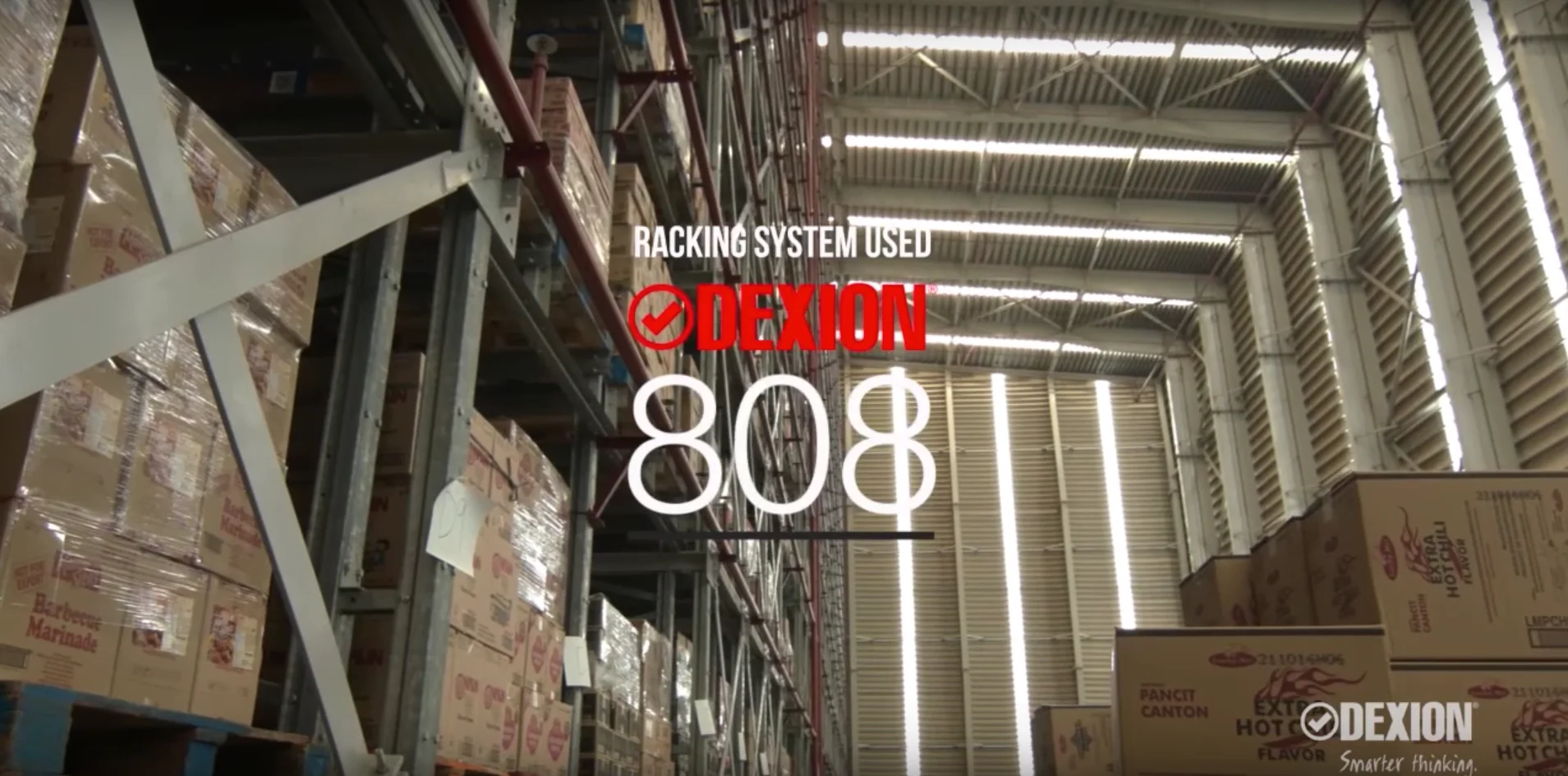

Faced with the challenge of rapid expansion, Monde Nissin required a warehouse solution to efficiently manage an increase in volume, equivalent to an additional 15,000 – 20,000 cartons daily, and to optimise space through high stacking of pallets. Dexion designed an ASRS racking system with the Dexion 808, an innovative racking system tailor-made for high bay warehouses to provide customers with added assurance and safety in high seismic zones. Dexion 808 comes in a wide selection of profile ranges and gauges to suit various applications.

In Kellogg’s case, the challenges were distinct. Their Minto warehouse struggled with limited storage capacity and an absence of automation, plus the pressing need for environmental consideration. Our response was the introduction of an Automated Storage and Retrieval System (ASRS), which not only increased storage capacity to 32,000 pallets but also enhanced overall efficiency. Environmentally, the facility’s design included energy-efficient lighting and recycling programs, while also reducing semi-trailer travel, thereby lowering greenhouse gas emissions.

In both scenarios, Dexion’s interventions were far from just minor tweaks. They represented major advancements in improving efficiency and sustainability in warehouse operations, specifically tailored to the nuanced needs of the Food & Beverage industry.